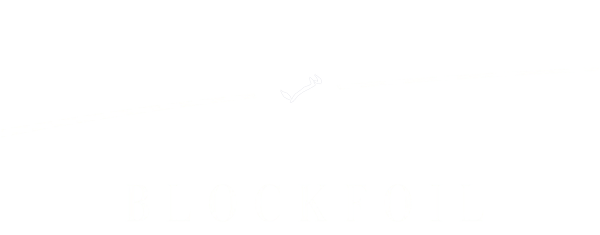

Foil layers – Before & After Application

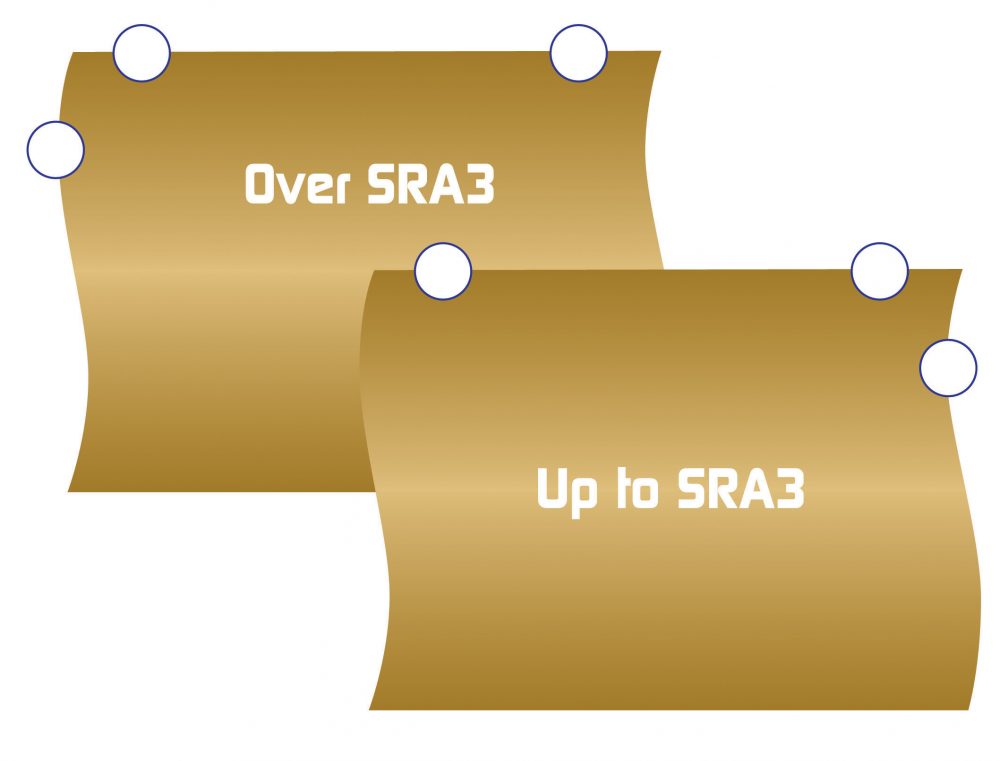

Grip Edge & Lay Dimensions

Here are some of our top foil printing tips:

- Foiling areas must be wax-free with a surface tension of 38 dynes per square cm or above, we might sometimes be able to work with a lower dyne level

- Allow at least 25mm from grip / lay edge to the area to be foiled

- Up to SRA3 put the grip edge should be at the top of the sheet and lay to the right edge

- Above SRA3 the lay edge to be to the left

- Always consider the choice of paper or board before offering foil printing as a finish

- Do not reverse out foil blocking areas to assist with registration

- Larger text size works better than smaller text and typefaces generally appear bolder once foiled. Be aware of this during the design phase

- If foiling two areas; a solid area and a fine area, expect to make two machine passes

- When preparing artwork for embossing always remember to accommodate for the bevel

- It is not yet possible to foil onto spot UV varnish or certain inks and other varnishes

- Always consider what will be on the reverse side of the hologram as it could detract from the hologram effect

- For the best hologram effects avoid square corners if possible

- If sealing use an aqueous rather than solvent-based sealant

We are always on hand to discuss jobs, produce proofs or trial various substrates. Please contact your nearest Blockfoil office – we’re always willing to help out.